Technologies Available * - Post Harvest Technology Centre, TNAU, Coimbatore. Source http://www.recipetips.com/images/glossary/m/milk_skim.jpg | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Technologies Available * - Post Harvest Technology Centre, TNAU, Coimbatore. Source http://www.recipetips.com/images/glossary/m/milk_skim.jpg | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

General Information

Quail is a collective name for several genera of mid-sized birds in the pheasant family Phasianidae, or in the family Odontophoridae. The quails are small, plump terrestrial birds. They are seed eaters, but will also take insects and similar small prey. They nest on the ground.

Breeds

Japanese quail and Bobwhite quails are the domesticated varieties of quail. Japanese quails are hardy, grows faster, has a short generation interval and is precocious. The meat is a delicacy. Specific lines developed for egg production as well as meat production are available.

Japanese quail

Japanese quails are hardier. They seldom have disease problems. Therefore, there is no need for routine immunization programme as with other poultry species. One major disease that affects Japanese quail is quail enteritis. This disease can be treated using appropriate antibiotics under Veterinarian’s advice.

The males and females can be separated based on physical appearance at about

4-5 weeks of age. The males have an even coloured rusty brown breast feathers with only few speckles of white. Where as the females have grey and black speckled breast feathers. The males also have a cloacal gland, which secretes a white foamy material. In contrast to most poultry, females are slightly heavier than males.

( Source: KVK, Namakkal )

Quails reach sexual maturity at about six weeks of age and weigh 120 g. Adults require 150-180 cm 2 per quail in laying cage. A feeder space of 2-3 cm per quail and water space of 2 cm has to be provided. For laying flock a photoperiod of 16 hours is desirable for good egg production. Layer quails may be provided with a mash containing 22% protein and 2650 K cal/kg of ME. Japanese quails reproduce well in all seasons. The eggs are laid from evening, the peak being between 6.30 – 7.30 p.m. The eggs laid during second year of lay are very much fewer than first year. Quail egg weighs around 10 g and is characterised by a variety of colour pattern ranging from dark brown, blue and white to buff each mottled with black, brown and blue. The egg shell is very thin and therefore breaks easily.

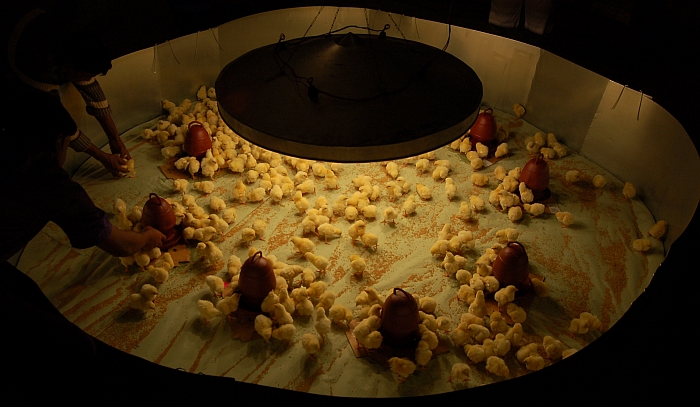

Care of quail chicks

The hatch weight of quail chicks is 6-7 g. They can be brooded either on deep litter or in battery brooders. However brooding the quail chicks in cages up to end of 3 weeks of age reduces initial mortality considerably.

The floor space suggested is 75 cm2/chick under the hover and 75 cm2/chick as run space. The brooder temperature recommended is 37oC at the beginning and this should be reduced at 2.7oC per week until the chicks are 4 weeks of age, by which time the quails would have grown their feathers very well. During brooding, water should be given in shallow dishes filled with marbles or pebbles to prevent quail chicks from drowning. The marbles or pebbles can be removed when the chicks are about 2 weeks of age.

The feeder space and water space recommendations are 2 and 1 linear cm per quail chick respectively. Quail chicks can be fed with a mash containing 27% protein and 2750 K cal / kg of ME up to end of 3 weeks of age and a mash containing 24% protein and 2750 K cal/kg of ME from 4th week of age. Maximum care has to bestow during the first two weeks of life of quail chicks.

( Source: KVK, Namakkal )

Good fertility can be obtained with a male-female ratio of 1:2. After introduction of male to a female flock, fertile eggs can be collected from 4th day onwards. Optimum fertility is obtained when the age of breeding flock is 8 months or less. Hatchability of fertile eggs rapidly declines when eggs are collected from older females. However, this effect is not observed with males.

Feed ration for Japanese Quails

| Ingredients | Starter (0-3 weeks) | Grower (4-6 weeks) | Layer (above 6 weeks) |

| Yellow maize | 43.25 | 44.25 | 46.25 |

| Groundnut cake | 20.00 | 20.00 | 20.00 |

| Soyabean meal | 22.00 | 14.00 | 10.00 |

| Rice polish | 3.00 | 10.00 | 8.00 |

| Unsalted dried fish | 10.00 | 10.00 | 10.00 |

| Mineral mixture | 1.50 | 1.50 | 1.50 |

| Salt | 0.25 | 0.25 | 0.25 |

| Shell grit | - | - | 4.00 |

| Total | 100.00 | 100.00 | 100.00 |

(Source: Kerala Agricultural University)

For every 100 kg of feed, commercially available vitamin mixture may be added at the rate recommended by the manufacturer

Shell of quail eggs are comparatively thinner and therefore should be handled carefully. Eggs should be held in an atmosphere free of dust and having a temperature of 14 to 16 0 C with a relative humidity of 70 to 80%. Eggs held even under these conditions should be used for hatching within 7 days of holding. The incubation period of quail egg is 18 days. Quail eggs can be incubated artificially using forced draft incubator at a temperature of 36.9 – 37.2 0 C with a relative humidity of 60 to 70%. Eggs should be turned 4 to 6 times daily upto 14 days of incubation.

|  |

Quail | Quail Egg |

( Source: KVK, Namakkal )

India has made considerable progress in broiler production in the last two decades. High quality chicks, equipments, vaccines and medicines are available. With an annual output of 41.06 billion eggs and 1000 million broilers, India ranks fourth largest producer of eggs and fifth largest producer of poultry broiler in the world. The broiler production has also sky rocketed at an annual growth rate of about 15 percent at present. Broiler farming has been given considerable importance in the national policy and has a good scope for further development in the years to come.

Classification of Breeds of Poultry

Americal Class

|  |  |  |

| New Hampshire | White Plymouth Rock | Rhode Island Red | Wyandote II |

Mediterranean Class

They are light bodied and well developed for high egg production.

|  |  |

| Leghorn | Minorca | Ancona |

English Class

|  |  |

| Australorp | Sussex | Orphington |

They are mostly utility breeds noted for their excellent flushing properties.

Asiatic Class

They are large bodied with heavy bones feathered shanks and poor layers.

Indian breeds

|  |  |

| Asil (Fighting purpose) | Kadacknath (Resh is black in colour) Bursa | |

Commercial Broiler strains

Eg. Cobb, Hubbard, Lohman, Anak 2000, Avian -34, Starbra, Sam rat etc.,

Commercial Layer Strains

Eg.BV-300, Bowans, Hyline, H & N nick, Dekalb Lohman etc.

Broiler: Broiler are young chicken of either sex, which are reared primarily for meat purposes and marketed at an age of 6-8 weeks

Grower: The management of birds during 9-20 weeks or to the point of laying is referred to as grower period.

Layer: The management of birds during 21-72 weeks of age for the purpose of laying eggs (egg production).

(Source: Dr.Paul Pricely Rajkumar, AC&RI, Madurai )

Breeds of Chicken

Chickens are grown for their egg and meat. Likewise they are classified as egg-type chicken and meat-types chickens. Egg type chickens are composed of stock that has been developed for egg production and are maintained for the principal purpose of producing chicks for the ultimate production of eggs for human consumption. Breeds of meat type chickens primarily include broilers, fryers, roasters, and other meat type chickens. Here broilers and other chickens are raised for their meat. Broilers are genetically selected for fast growth and raised for meat rather than eggs e.g. White Synthetic Male line (WSML), white synthetic dam line (SDL), coloured synthetic male line (CSML), coloured synthetic female line (CSFL), introgression of frizzle gene etc.

Native breeds of egg type chicken in India

Breed | Body weight (20 weeks) | Age at sexual maturity (days) | Annual egg production (No.) | Egg weight at 40 weeks (g) | Fertility | Hatchability FES (5) |

| Aseel | 1220 | 196 | 92 | 50 | 66 | 63 |

| Frizzle | 1005 | 185 | 110 | 53 | 61 | 71 |

| Kadaknath | 920 | 180 | 105 | 49 | 55 | 52 |

| Naked neck | 1005 | 201 | 99 | 54 | 66 | 71 |

(Source: Central Avian Research Institute)

Indigenous Breeds

The common control hen, the desi, is as a rule the best mother for hatching. She is a good forager. Some of the Indian flows resemble the Leghorn in size and shape, but have poor laying qualities. They are Found in various colours. one variety found in India resembles the sussex or Plymouth Rock in shape but is smaller. These birds lay family well and are more common in the eastern parts of the country.

The Indian birds are mostly non-descripts, and are of very little value as layers. They have several local breed names such as Tenis, Naked Neck, Punjab, Brown, Ghagus, Lolab, Kashmir Faberella, Tilri, Busra, Telllicherry, Danki, Nicorai and Kalahasti. There are only 4 pure breeds Karaknath and the Busra. The last occurs in western India. A large number of flows of different size, shapes and colours, and for the most part resembling the jungle fowls, are found all over India. They vary in appearance according to the locality in which they have been bred. These with Chittagong, Aseel, Langshan or Brahma blood in them are bigger in size and better in meat quality than the common flows.

Asil

Asil is noted for its pugnacity, high stamina, majestic gait and dogged fighting qualities. The best specimens of the breed, although rare, and encountered in parts of Andhra Pradesh, Uttar Pradesh and Rsjasthan. The most popular varieties are peela (golden red), yarkin (black and red), Nurie 89(white), kagar (black), chitta (black and white silver), Teekar (brown) and Reza (light red). Although poor in productivity, the birds of this breed are well-known for their meat qualities. Broodiness in most common and the hen is a good sitter and efficient mother. They possess pea combs which are small but firmly set on head. Wattles and ear lobes are bright red, and the beak is hart. The face is long and slender, and not covered with feather. The eyes are compact, well set and present bold looks. The neck is long, uniformly thick but no fleshy. The body is round and short with broad breast straight back and close - set strong tail root. The general feathering is close, scanty and almost absent on the Brest. The plumage has practically no fluff and the feathers are tough. The tail is small and drooping. The legs are strong, straight, and set well apart. Standard weight (kg): Cocks, 4 to 5; hen 3 to 4; cockerrels, 3.5 to 4.5; pullets, 2.5 to 3.5.

Asil

Karaknath

The original name of the breed seems to be Kalamasi, meaning a fowl with black flesh. However, it is popularly known as Karaknath. The eggs are light brown. The day-old chicks are bluish to black with irregular dark stripes over the the back. The adult plumage varies from silver and gold-spangled to bluish-black without any spangling. The skin, beak, shanks, toes and soles of feet are slatelike in colour.The comb, wattles and tongue are purple. Most of the internal organs show intense black colouration which is pronounced in trachea, thoracic and abdominal air-sacs, gonads and at the base of the heart and mesentery. Varying degrees of block colouration are also seen in the skeletal muscles, tendons, nerves, meninges, brain etc. The blood is darker than normal blood. The black pigment has been due to deposition of melanin, The flesh although repulsive to look at, is delicious. A medium layer, lays about 80 eggs per year. The bird is resistant to diseases in its natural habitat in free range but is more susceptible to Mareks disease under intensive rearing conditions.

(Source: Dr.Acharya, Handbook of Animal Husbandry)

Kadaknath |  Naked neck ( Photo source: KVK Namakkal ) |

Other commercial breeds of broiler chicken in India

Breed | First egg | 50% Production | Peak production | Livability | Egg production peak | Feed efficiency | Egg weight | Net egg production (72 weeks) |

| ILI-80 | 17-18 weeks | 150 days | 26-28 weeks | Grower (96%) Layer (94%) | 92% | 2.1 | 54 g | 280 eggs |

| Golden-92 | 18-19 weeks | 155 days | 27-29 weeks | Grower (96%) Layer (94%) | 90% | 2.2 | 54 g | 265 eggs |

| Priya | 17-18 weeks | 150 days | 26-28 weeks | Grower (96%) Layer (94%) | 92% | 2.1 | 57 g | 290 eggs |

| Sonali | 18-19 weeks | 155 days | 27-29 weeks | Grower (96%) Layer (94%) | 90% | 2.2 | 54 g | 275 eggs |

| Devendra | 18-19 weeks | 155 days | 27-29 weeks | Grower (97%) Layer (94%) | 90% | 2.5 | 50 g | 200 eggs |

(Source: Central Avian Research Institute)

Commercial available meat-type chicken in India

| Breed | Weight at six weeks (g) | Weight at seven weeks (g) | Food conversion ratio | Livability (%) |

B-77 | 1300 | 1600 | 2.3 | 98-99 |

CARIBRO-91 | 1650 | 2100 | 1.94-2.2 | 97-98 |

CARIBRO Multicoloured | 1600 | 2000 | 1.9-2.1 | 97-98 |

CARIBRO Naked necked | 1650 | 2000 | 1.9-2.0 | 97-98 |

Varna | 1500 | 1800 | 2.1-2.25 | 97 |

Basically two systems are commonly followed in our country

1. Cage system

2. Deep litter system

I. Cage system: The cage system of rearing birds has been considered as a super intensive system providing floor area of 450-525 sq.cm. (0.6-0.75 sq.feet) per bird. In cage the birds are kept in one, two or three per cage, arranged in single or double or triple rows.

|  |

Cage system

Advantages

1. Greater number of birds is reared per unit of area

2. Facilitates correct maintenance of records

3. Helps in identifying poor producers and prompt culling

4. Control of vices of poultry cannibalism and egg eating

5. It helps in production of clean eggs

6. Removal of stress factors

7. Easy control of parasitic disease like coccidiosis and worm infestation

8. Prompt steps to control feed wastage.

9. The cage method of housing is ideal for the area of moderated climate conditions where the day temperature in summer does not high and temperature does not fall too low.

10. Egg production of caged layer was reported to be more then those kept in deep litter system.

11. Feed efficiency and egg weight were better in caged birds than the laying flock under deep litter system.

Disadvantages:

1. Difficulties in ensuring proper ventilation to birds especially in summer season and under very high densed conditions.

2. Incidence of leg problem, cage layer fatigue, fatty liver syndrome, flies and obnoxious gases in the house will be on increases

3. Hysteriosis of chicks

Cage fatigue: Cage fatigue is considered to a physiological derangement of mineral electrolytes imbalance. Leg weakness is common in caged birds.

Cage fatigue

Fatty live syndrome: It is a problem met with caged layers due to increased deposition of fat in the body resulting in death due to internal hemorrhage. Increasing the protein level and the diet strengthened by the addition of choline, vitamin B12, inositol and vitamin-E may be helpful in reducing the incidence of problem.

Proper ventilation, correction of light-intensity, duration, temperature, ideal environmental conditions, and maintenance of comfort in cages will check the conditions of hysteria of chicken in cages.

II. Deep litter system: Deep litter system is commonly used in all over the world.

|  |  |

Deep litter system

Advantages:

1. It is an economical

2. Hygienic, comfortable and safe to birds

3. Built up litter supplies vitamin B12 and Riboflavin to the birds

4. Controls diseases and vices

5. It increases the efficiency of production

6. Materials such as paddy husks saw dust, dried leaf, chopped straw and groundnut kernels depending upon the availability can be used as litter materials.

Points to be considered while adopting deep litter system

1. The deep litter system should always kept dry.

2. Only right numbers of birds should be housed

3. The house should be well ventilated

4. The litter should be stirred at least once in a week-wet litter if any should be replaced immediately with new dry litter and birds must be fed a balanced ratio.

5. The time starting deep litter system should be in the dry period of the year as it allows sufficient time (At least two months) for bacterial action.

6. Placing of water should be given due attention to keep litter dry.

(Source: Dr.Paul Pricely Rajkumar, AC&RI, Madurai )

Size of flock: Larger size units are more economical than smaller ones under commercial conditions. A unit of 2000 layers is usually considered as economical for commercial egg production. In the case of broilers a unit intake of 250 chicks per week is usually considered as viable.

Stock: Procure the best quality chicks. No amount of good management can convert poor quality chicks into good layers or broilers. More profit can be made in a commercial unit by procuring day old pullet chicks. In broiler units, straight-run chicks would give equally good performance.

Random sample poultry performance test: Government of India has established random sample test units for layers and broilers in four locations, viz. Bangalore, Bombay, Bhubaneswar and Delhi. The test results are published annually and give information about the performance of the various strains and breeds of chicken under identical conditions. This information would help in the choice of the stock.

Number to be procured: In determining the number to be procured, normal losses that might occur due to death and culling have to be allowed. For each 1000 layers to be housed, procure 1100, day-old pullet chicks or 1050 growing pullet chicks or 1000 ready-to-lay pullets. In the case of broilers, the corresponding number would be 250-day-old straight-run chicks for 250 broilers to be marketed at 6-7 weeks of age.

Artificial brooding: Chicks newly hatched out require supplementary heat till they grow feathers. The period of brooding is usually up to 4-5 weeks of age and a little longer in cold season. Artificial brooding can be carried out in deep litter houses or in electrically operated brooder batteries.

|  |  |

Artificial brooding

Floor space, feeding space and watering space for chicks

| Age weeks | Floor space Sq.ft./Chick | Feeding space inches/chick | Watering space inches/chick |

| 1 | 0.2 | 1.5 | 0.5 |

| 2 | 0.2 | 2.0 | 0.7 |

| 3 | 0.3 | 2.0 | 0.7 |

| 4 | 0.4 | 2.5 | 0.8 |

| 5 | 0.6 | 2.5 | 0.8 |

| 6 | 0.8 | 3.0 | 1.0 |

| 7 | 0.9 | 3.0 | 1.0 |

(Source: Central Avian Research Institute)

On the deep litter, provide 700 cm2 floor area per chick till 8 weeks of age. In a hover with one m diameter, 250 chicks can be brooded. The hover can be metal or bamboo basket fitted with a heat source. The size and number of the hovers depend on the number of chicks to be brooded. Units of 250 chicks are ideal for efficient management. The hover can be placed at appropriate height from the floor either by hanging it from the roof or by placing it over bricks or stones so that chicks can go in and out easily. Temperature required for brooding is 1 –2 Watt/chick. Use five bulbs of 60 Watts per unit of 250 chicks.

Electricity is the common source of heat used. Electric bulbs of multiple units are preferred over single bulb to cover the wattage. Infra-red bulbs can also be used for brooding. Hover is not necessary when infrared bulbs are used. The number of bulbs to be used depends on the number of chicks to be brooded. The rule of thumb is that one Infra-red bulb of 250 watts for every 250 chicks. Position the bulb 50 cm above litter.

The requirement of chicks for additional warmth decreases as they grow. The warmth as measured by thermometer at 5 cm (2 inches) above the floor level should be checked everyday.

Temperature requirement of chicks during different ages

| Age in weeks | Temperature under hover, at 5 cm above floor ( °C) |

| 0-1 | 35 |

| 0-2 | 32 |

| 2-3 | 29 |

| 3-4 | 26 |

| 5-5 | 23 |

The distribution of chicks under the hover is a better indication of warmth than the thermometer. If the chicks are active, busy eating and drinking, it indicates that the temperature under the hover is comfortable. Generally one watt per chick appears satisfactory under our climatic conditions.

Litter management: Litter materials such as wood shavings; saw dust, paddy husk, peanut shell, paddy chaff, chopped straw and such other materials that absorb moisture well can be used depending upon the cost and availability. Spread the litter to a depth of 5 cm on the floor before introducing chicks and build it up to a depth of 15 cm by adding litter material, at the rate of about 2 cm per week. This would require approximately 10 kg of litter material/sq.meter. Litter should be raked thoroughly at frequent intervals, say at least twice a week, during the cold and rainy season, once a week during the hot season and the day after deworming. Litter should be kept dry always. During the cold and rainy season and on the area of floor where watering utensils are placed, special attention should be paid daily to check the litter condition. If required, top-dress with fresh litter. It is desirable to use dry lime at the rate of 10 kg per 10 m3 and rake the litter.

Light: Artificial light should be discontinued from the time the chicks no more require additional warmth. Dim light of a 40-watt bulb for every 250 chicks can be provided during the night for broiler chicks.

(Source: www.vuatkerala.org)

BUTTER The fat content of butter is generally about 80%. The non-fat components of butter consist of moisture, milk solids not fat and sal...

.jpg)